-

Make a Call : +8615559090996

-

Get A Estimate : senko@fjsenko.com

你要买什么?

你要买什么?

Make a Call : +8615559090996

Get A Estimate : senko@fjsenko.com

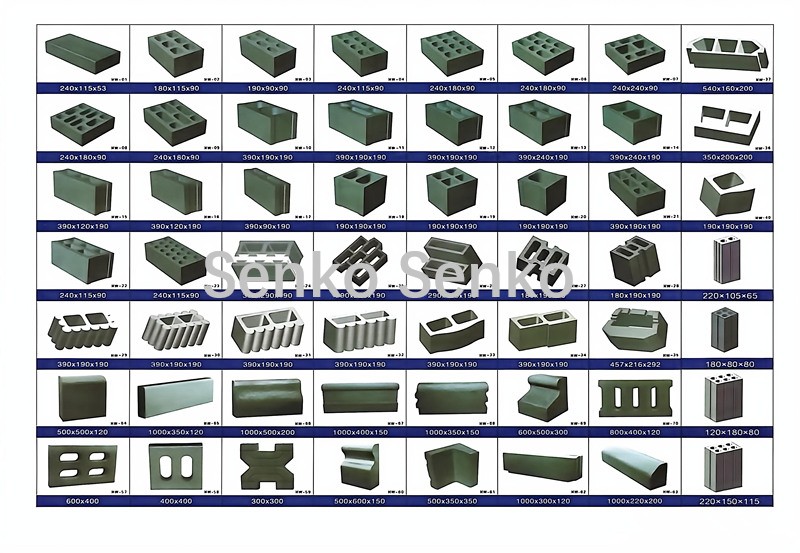

我们以沙子、砾石和水泥为原料,并添加大量的粉煤灰、矿渣、钢渣、煤灰、陶粒、珍珠岩和其他工业废料,生产各种外墙砌块、内墙砌块、PC仿石透水砖、装饰墙砌块、楼板、路堤砌块、连锁砌块、路缘石和其他砌块。我们还可以加装彩色织物贴合装置,生产各种规格的彩色路面砖。

手动砖/砌块成型机(模型:SKSM4-15)

模具准备: 清洗模具,并涂抹脱模剂(例如废机油)以防止粘连。

填充材料: 将预拌混凝土或粘土原料填充到模腔中。

初步压实: 通过手动预压或振动(如果配备基本振动功能)进行初始排气和压实。

施加高压: 利用杠杆或手动液压泵对材料施加持续的高压,确保在模具内形成致密的成型。

脱模: 释放压力,然后通过顶出机构或直接打开模具取出成型的砖块。

养护: 将砖块转移到养护区进行自然风干或蒸汽养护,以达到最终强度。

产品优势:

1.本机采用上模推拉和自动刮刀,操作简便,堪比大型设备。所有动作均由按钮控制,操作简单。

2. 该机是经过改进的机型,设计合理,性能优良,配备超强振动电机。它生产的砖块质量好、密度大、强度高。

参数列表

|

不。 |

物品 |

规格 |

|

1 |

模型 |

SKSM4-15 |

|

2 |

升降电机 向上模具前后移动 振动 |

2.2千瓦 0.75千瓦 1.1千瓦 |

|

3 |

整机尺寸 |

1900*1700*2000毫米(长*宽*高) (可定制) |

|

4 |

模具尺寸 |

850*500*230毫米 (可定制) |

|

5 |

空心块的尺寸 (一行包含 4 个代码块) |

400*200*200毫米(长*宽*高) |

|

6 |

周期 |

25-35秒/时间 |

制成品:

视频链接