Block Rotary Strapping Machines: Top vs. Bottom Rotation Comparison

Mar 04, 2026

In the world of concrete block and brick production, efficient packaging is the final critical step before products reach the customer. Among the most innovative solutions in this space are rotary strapping machines—specifically, the top-rotation and bottom-rotation (through-beam) strapping systems. But how do they compare?

Understanding Rotary Strapping Machines

Both top-rotation and bottom-rotation strapping packing machines are designed to automatically secure block stacks with plastic straps, facilitating safe handling and transport. The "rotation" refers to how the block stack is turned to apply crosswise straps, while through-beam describes the mechanism where the strapping guide enters pre-formed gaps in the stack to feed the strap .

While specific direct comparisons are rare in manufacturer literature, we can analyze their general operational principles and inferred advantages based on common engineering trade-offs.

Top-Rotation vs. Bottom-Rotation: A Comparison

To help you understand the key differences, here is a breakdown of the potential advantages and disadvantages of each system:

Feature Top-Rotation穿剑 Strapper Bottom-Rotation穿剑 Strapper

Mechanism Grips the top of the block stack to lift and rotate it. Rotates the stack from below using a turntable or rollers in the conveyor.

Potential Advantages - Can handle unstable or loosely stacked blocks by holding them firmly from above. - Typically allows for a simpler, more accessible machine design .

- The rotating mechanism is kept clear of debris that accumulates on the conveyor. - Suitable for very heavy or tall stacks where top-gripping might be impractical.

- May offer more precise rotation for stacks with varying bottom surfaces. - Often enables faster rotation cycles as the stack doesn't need to be lifted first .

Potential Disadvantages - More complex mechanism with moving parts overhead, potentially higher maintenance. - Rotating mechanism integrated into the conveyor line can be prone to dust and debris buildup.

- Requires sufficient overhead clearance in the facility. - May struggle with stacks that have poor bottom surface integrity or are prone to tipping.

- Cycle time may be slightly longer due to the lift-and-rotate action. - The rotation mechanism occupies floor space along the production line.

The choice between top and bottom rotation often depends on your specific product mix, plant layout, and maintenance preferences. Some sources highlight that integrated rotation systems allow for efficient bidirectional strapping with a single machine, saving both cost and floor space .

Senko's Holistic Approach: More Than Just a Machine

Choosing the right strapping machine is just one piece of the puzzle.Quanzhou Senko Intelligent Equipment Manufacturing Co., Ltd. distinguishes itself not just as an equipment manufacturer, but as a comprehensive service provider for production lines and whole-plant integration. Here’s what Senko can offer its clients:

1. Expert Consultation and Needs Analysis

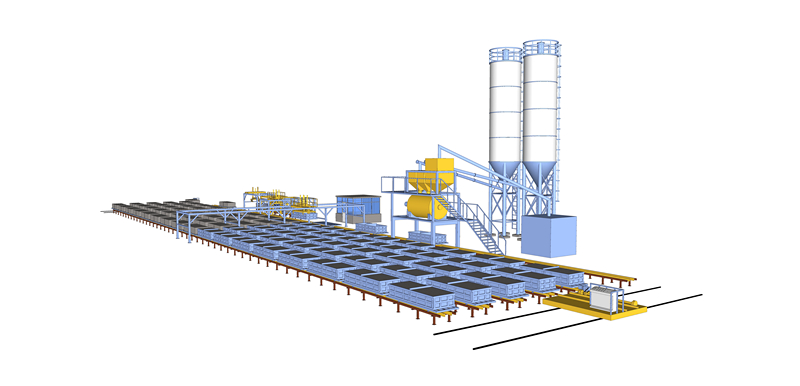

Before a machine is ever built, Senko works closely with clients to understand their specific production goals. This includes analyzing block types (e.g., standard bricks, hollow blocks, insulating blocks), production volume, existing plant layout, and packaging requirements . This ensures the recommended solution—whether top or bottom rotation—is the perfect fit.

2. Customized Equipment Design and Manufacturing

Leveraging its manufacturing expertise, Senko can tailor equipment to specific client needs. This goes beyond just the strapping machine to include:

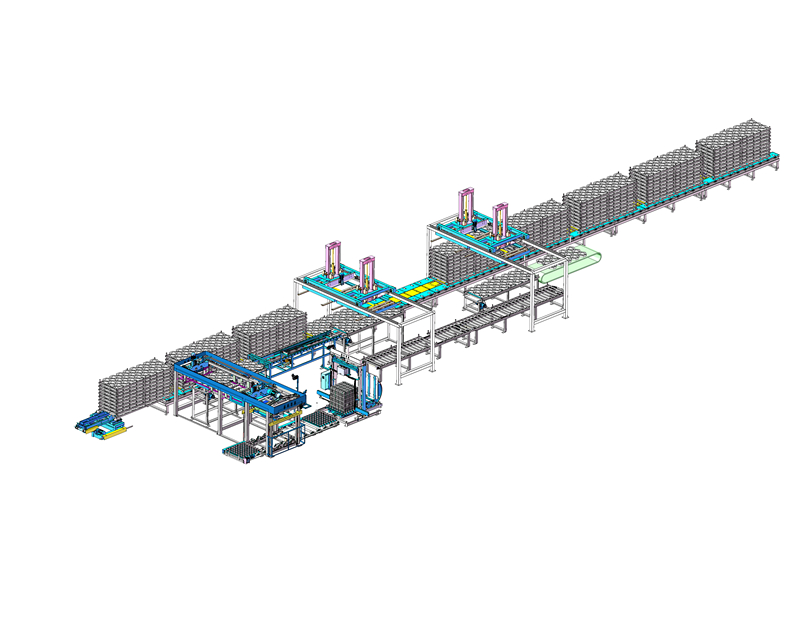

· Integrated Handling Systems: Custom infeed and outfeed conveyors that seamlessly connect to your existing machinery.

· Forklift Pocket Formation: Intelligent systems that ensure straps are applied without obstructing pre-formed forklift pockets in the block stack .

· Flexible Packaging Modes: Options for pallet-less packaging or pallet cycling systems based on client preference .

3. Whole-Plant Integration Services

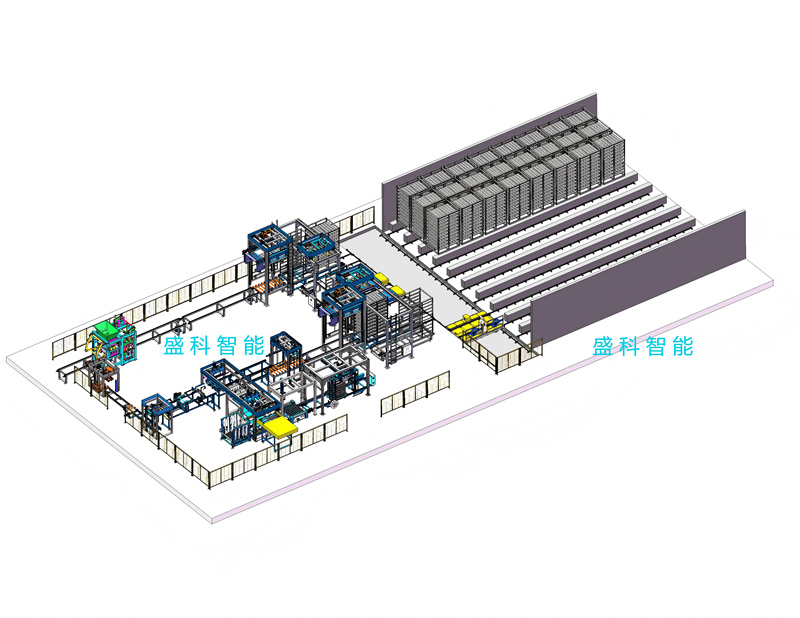

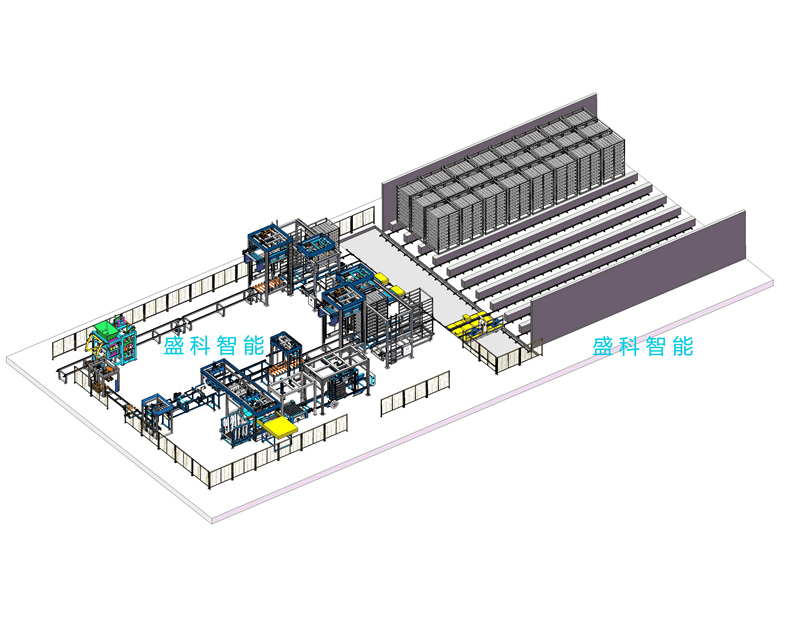

Senko’s core strength lies in its ability to act as a single-source integrator. This means they can manage the entire project, from the initial design to the final commissioning of a fully integrated production line. This "whole-plant" approach ensures that every component—from the block forming machine to the packaging line—works in perfect harmony. It alleviates the client's burden of coordinating between multiple suppliers.

4. Comprehensive After-Sales Support

The relationship doesn't end with installation. Senko provides ongoing support, including:

· Installation and Commissioning: Expert teams to ensure smooth setup and startup.

· Training: Comprehensive training for your operators and maintenance staff.

· Spare Parts and Maintenance: A reliable supply of genuine parts and proactive maintenance services to maximize uptime. Features like modular strapping heads in modern machines facilitate quick replacement and offline maintenance, reducing downtime .

Conclusion

When deciding between top and bottom-rotation strapping machines, consider your specific product characteristics and operational priorities. Both technologies offer pathways to automation, reducing labor costs and improving packaging consistency .

However, the true value lies in partnering with a provider that sees the bigger picture. With泉州Senko Intelligent Equipment Manufacturing Co., Ltd., you gain more than a piece of equipment; you gain a partner capable of engineering, integrating, and supporting a complete production solution. From expert consultation to whole-plant integration and dedicated after-sales care, Senko is equipped to help your block-making business achieve new levels of efficiency and reliability.

For more information on how Senko can optimize your production line, please contact us today.

https://www.senkomachine.com/category/brickblock-packing-machines